The Challenge and Breakthrough of 'Doing Everything In-House': How Union Tool Achieved Efficient GPU Resource Management with AI-Stack

Plan to Introduce AI Technology for Product Image Inspection

Union Tool, a manufacturer of ultra-hard drills, end mills, and metal-processing equipment, is a world-leading producer of PCB drills that bore minute holes used to mount components and form wiring on printed circuit boards. Before the highly integrated CPUs, GPUs, and other components made by the world’s top semiconductor makers can operate correctly, the “holes” drilled by Union Tool are indispensable.

The key that supports Union Tool’s high level of technology lies in its thorough “in-house production” strategy—not only does it make the products, it also develops the production equipment itself. “Our company has a culture of ‘doing everything ourselves.’ To realize the products required by customers, such as PCB manufacturers, we even develop the manufacturing equipment and manufacture products in a custom manner,” says Ryo Shinozaki, Deputy General Manager of the Production Technology Department.

[Image] Ryo Shinozaki, Deputy General Manager, Production Technology Department, Union Tool

Union Tool has many customers from China, North America, and other regions—mainly GPU and CPU package-substrate manufacturers—and provides customized products. The company routinely produces more than 1,000 types of products, and the number of prototype drill edges alone exceeds 10,000.

Naturally, "inspection" plays a vital role in the manufacturing process. Two inspection methods are used: full inspection and sampling inspection. Because the tip of a PCB drill is thinner than a strand of hair and cannot be identified with the naked eye, operators must inspect it through a microscope.

This work not only imposes a heavy burden but also requires considerable skill. Considering future labor shortages, an inspection system that relies on manual work will be difficult to sustain. For this reason, since 2023, Shinozaki’s Production Technology Department has been studying the possibility of using AI for image inspection.

“We photograph product images with a camera to detect defects caused by dirt or foreign matter. The problem is processing speed. Experienced operators can visually inspect several drills at once, processing multiple pieces per second. To reach the same level as machines, AI must process quickly and increase throughput,” Shinozaki says.

To solve this issue, the company ultimately developed an AI inspection device that uses GPUs.

Mechanism of the AI Inspection Device Trained on Good-Product Images

The completed AI inspection device first photographs a large number of passed (good) product images and lets the AI learn from them. There is a reason for not using images of defective products for learning.

“The defect rate of drills is extremely low, and there are many different defect conditions, so in practice, it is hard to prepare a sufficiently varied set of defective samples. For that reason, we chose to train the AI on good-product images and adopted a mechanism that judges ‘anything that is not a good product’ as defective,” Shinozaki explains.

While good-product training was underway, a camera device for inspection was also developed. To photograph the minute drill tip, a special structure that rotates the drill while shooting was required; after repeated trials, the device was completed, taking about one year.

Implement 'AI-Stack' for Efficient GPU Resource Sharing

Within the Production Technology Department, Section 2 is responsible for software development. Section Chief Shin-ichirō Hayashi and Assistant Section Chief Takaya Shimbo handled the development of the AI image-inspection system. "At first, we installed GPUs in our respective PCs and began model training with two machines. The learning and program development themselves went smoothly, but we spent a lot of time setting up the GPU environment," Hayashi says.

[Image] Shinichiro Hayashi, Production Technology Department, Union Tool

To realize the AI-based product inspection system, Union Tool is developing software and hardware in parallel and has now reached a critical phase, aiming for official operation within 2025. Furthermore, the Production Technology Department also hopes to further enhance production efficiency through AI and intends to implement higher-performance GPUs.

As development progressed, the number of personnel in the department increased. "If every PC had its own GPU, the cost would be enormous, and we would have to configure each environment separately, which is a huge burden. NVIDIA GPUs do support resource partitioning, so we wondered if the team could share a GPU efficiently, but the architecture is complicated and the setup is cumbersome," Shinozaki notes.

High-end GPUs designed for data centers are built for large-scale applications and are over-specified for the company's needs. While the team was interested in GPU partitioning but lacked a concrete method, a proposal from Macnica at a May 2023 exhibition provided a breakthrough.

"Macnica introduced us to 'AI-Stack,' a tool developed by Taiwan's INFINITIX. Its functions seemed to fit our needs perfectly, so we decided to test it first," Shinozaki says. Hayashi and Shimbo connected to a cloud evaluation environment provided by Macnica to test AI-Stack's functions, and finally determined that the tool could indeed improve GPU utilization inside the company, so they decided on full adoption.

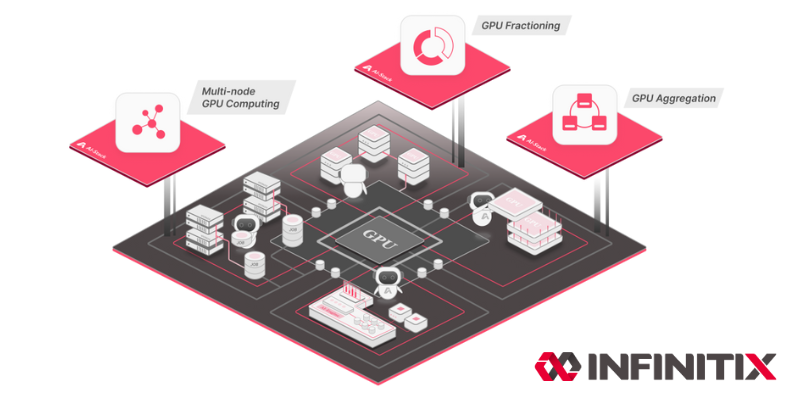

In fact, AI-Stack's appeal is not limited to GPU resource partitioning; even more attractive is its resource-management efficiency. According to preset policies, it can automatically allocate resource pools composed of one or multiple GPUs to individuals or teams. Users can set conditions such as the minimum/maximum GPU quota per team. For example, when GPU resources are completely idle, one team can monopolize all resources; when other teams start using them, the system reallocates automatically. This mechanism raises the usage efficiency of valuable GPUs and achieves flexible, efficient management.

AI-Stack, developed by INFINITIX, is industry-leading AI infrastructure-management software that greatly accelerates AI adoption. By integrating GPU partitioning, aggregation, cross-node computing, heterogeneous-cloud management, an intuitive graphical UI and environment-construction features, it maximizes GPU utilization and flexibly supports rapid AI iteration.

Continued GPU Utilization Even During Holidays

After AI-Stack was introduced, sharing GPU resources among team members became extremely simple and is highly rated by the Production Technology Department.

“When an AI development project starts, we launch a container and build the required environment. If we had to allocate GPUs manually, a specialist would have to set them via Kubernetes each time—tedious and time-consuming. Since AI-Stack was introduced, those complex steps are unnecessary; we can focus solely on designing training data and development,” Shimbo says.

[Image]Takaya Niibo, Production Technology Department, Union Tool

Hayashi highly praised AI-Stack's scheduling features. "AI-Stack not only partitions GPUs, automatically optimizing resource allocation when multiple users are working simultaneously, but it also has a very convenient 'GPU reservation' function. For example, when performing large-scale data training, you can schedule tasks in a queue in advance for sequential execution. If we reserve GPU tasks before leaving work on Friday, the processing results will be ready by Monday morning, eliminating the need for someone to come into the office on weekends to start GPU computing like before."

Currently, the company has installed a server with two NVIDIA RTX A5000 GPUs at its Nagaoka Technical Center, while its headquarters in Tokyo has a higher-performance NVIDIA H100. All GPUs are centrally managed on the AI-Stack platform and are expected to be opened to departments beyond Production Technology in the future.

Fostering Internal Talent Able to Leverage AI

Through AI-Stack, Union Tool successfully established an infrastructure that can efficiently partition and utilize GPU resources. Shinozaki frankly notes, however, that the company still lacks personnel who can truly exploit AI.

"In management departments, there are many tasks well suited to AI-driven efficiency. To achieve that, we must foster AI-capable personnel across development, manufacturing and management. So we transferred three colleagues from other departments to Production Technology to launch a project exploring business reform through AI."

One project member, Shun-ichi Iketsu (PCB Tool Development Section, Tool Technology Division 1), is a drill designer who hopes to enhance the utilization of internal document resources via AI. "Inside the company, there are many reports containing technical information, but this knowledge hasn’t been effectively used. These documents often include confidential customer specs, so we can’t let an external AI learn them. We’re considering building an internal AI environment and creating a local LLM to process the content."

[Image] Shun-ichi Iketsu, Production Technology Department, Union Tool

Union Tool’s tools are mostly custom products; PCB material and surface finish vary per customer. Related technical documents are a valuable knowledge trove in new-product development. Iketsu is devising a mechanism that combines generative AI with internal information search, using RAG (Retrieval-Augmented Generation) to turn accumulated knowledge and experience into more accurate AI answers.

As AI spreads across more departments, the GPU-partitioning function of AI-Stack will create even greater value.

High Praise for Macnica, Which Stayed Beside Them Throughout the Introduction Process

In Union Tool’s AI-Stack rollout, Shinozaki and colleagues unanimously call distributor Macnica a most reliable supporter.

"Honestly, during the AI-Stack introduction, our culture of 'doing everything ourselves' became an obstacle. We wanted to complete all settings internally, which took a lot of time. The person in charge at Macnica stayed quietly by our side, respected our approach, and patiently watched over the process. They probably wanted to jump in and help much earlier (laughs), but only offered assistance when we were truly stuck. That impressed me deeply," Shinozaki says.

Utilizing AI-Stack, Union Tool has built an environment that can manage GPUs efficiently and intends to apply it not only to production technology but also to streamline the entire company’s operations through AI. Upholding its spirit of "doing everything ourselves," while flexibly adopting excellent tools, the day when Union Tool fully realizes AI utilization is already in sight.

Produced by ITmedia Inc. © 2025 ITmedia, Inc. All Rights Reserved.